Improve Quality Control with ERP Software in Manufacturing

Delivering products of superior quality is important. Organizations seeking to maintain client loyalty in the evolving industry are a must. The capacity to track product quality across the supply chain has become critical. In this pursuit, ERP systems emerge as invaluable assets.

ERP software can enhance quality control measures in manufacturing. With real-time tracking to data integration, businesses can gain concurrent insights. This can provide excellence in production processes.

In the production process, quality reigns supreme, every step is taken to quality checks. Quality is also important to meet customer and regulatory requirements. By using ERP systems, manufacturers can enforce and establish quality standards.

Manufacturing ERP enables the business to track and maintain standards. Standardization reduces bottlenecks to further improve on-time delivery.

All About Manufacturing ERP

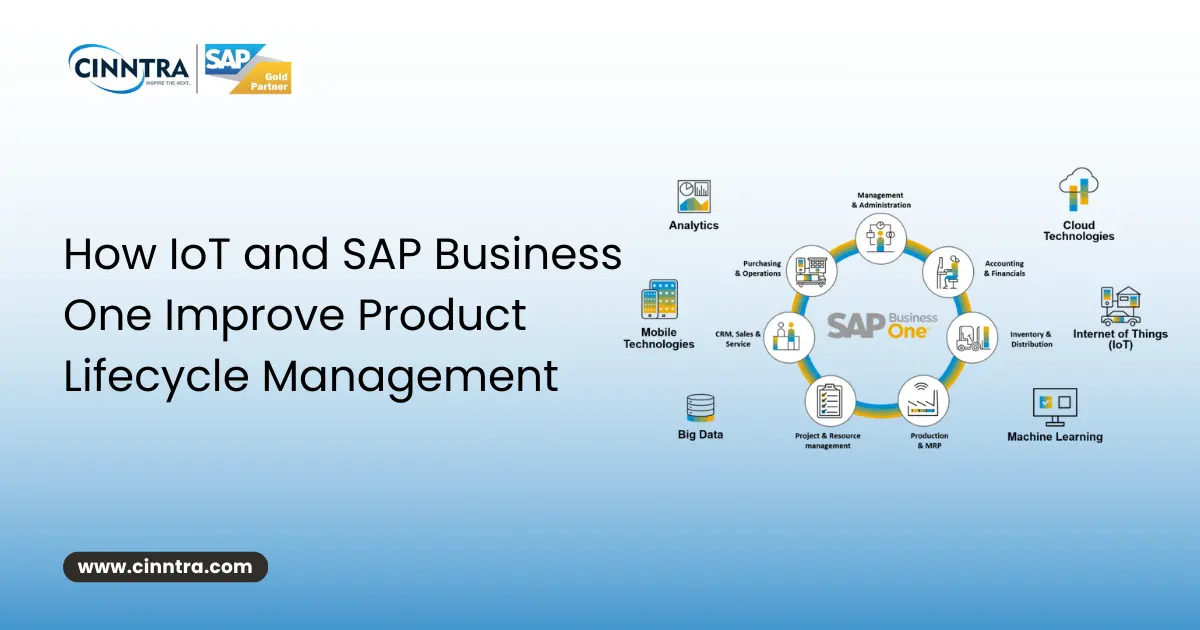

Manufacturing ERP is an Enterprise Resource Planning system. This system is developed to support manufacturers. The manufacturers can gain insights into operations by planning, managing, and delivering functionalities. Further ensuring a flexible and integrated business management platform for manufacturing companies.

Utilizing an ERP Software Used in Manufacturing

ERP software works as a management software that increases organizational efficiency. This is done by managing and improving company resource utilization. Manufacturing businesses can improve growth and profitability by reducing resource requirements. While maintaining quality and performance, businesses promise customers excellent solutions.

Manufacturing ERP software helps in managing operations, from shop floor to supply and inventory planning. It automates production and manages inventory to streamline processes for quality control with ERP. This software provides better visibility and control, enabling faster, more informed decisions. Cloud-based ERP software also enhances agility and competitiveness in the digital marketplace.

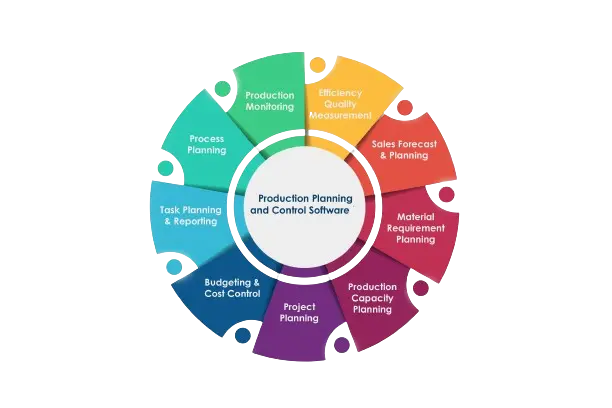

Key Features and Functionalities of ERP System:

Manufacturing ERP solution provides a wide range of features and functionalities. These are designed to improve operational efficiency. Some of the key features are as follows.

1. Quality Control:

ERP systems provide essential tools to assist manufacturers with quality control and ensure regulatory requirements. This also aligns the business products with quality compliance and delivers customers with optimized products. Quality control with ERP is data-oriented and automated with tools and enhanced technologies.

2. Inventory Management:

ERP enables real-time insights on managing inventory for the business. With the tracking on a concurrent basis, manufacturers can optimize stock levels and prevent situations of inventory stockouts or overstocks.

3. Production Scheduling:

ERP systems provide advanced planning capabilities to help enterprises develop production schedules that match customer demand and available resources, minimizing production bottlenecks and enhancing on-time delivery.

4. Data Integration:

ERP systems integrate data from a myriad of areas to provide a distinctive overview of the business. Data integration offers informed decision-making and better flexibility in responding to ongoing market conditions.

The functions of ERP software for Manufacturing are as follows.

1. Analyzing KPIs and Quality Metrics:

A manufacturing ERP is used to preview quality measures and key performance indicators and track the company's process. Reviewing statistical process control and statistical quality control can help identify ways to improve quality management. You can also be more particular, such as reviewing discrepant material reports (DMR) to determine which parts are failing inspection.

2. Real-Time Data Insights:

ERP systems help with 24/7 insights into key performance indicators and essential business parameters. This provides decision-makers with accurate information to facilitate proactive decision-making.

3. Fiber Forward Traceability:

An ERP provides end-to-end traceability for your organization's quality control. The system provides real-time data for materials and products, allowing you to identify flaws early. You can also view past quality management data such as nonconformance reports, initial article inspections, and item rejections. With so much information at your disposal, it's simple to audit your operations and uncover weak links in your supply chain.

4. Administrative Repository:

ERP systems function as a centralized depository for all pertinent data in the organization. This eliminates any data silos and guarantees that everyone in the business is working with the updated information. Manufacturers can reduce errors and conflicts by using integrated data to ensure consistency in product specs, pricing, and customer information. Changes made in one department or phase of manufacturing are quickly mirrored throughout the system which further helps in real-time data synchronization.

Compelling Benefits of ERP for Manufacturing Businesses

There are many valuable operational benefits of having a modernized and integrated ERP system. The compelling benefits of ERP for manufacturing are as follows.

-

Minimizing redundancies and automating processes to increase efficiency.

-

Improving supply chain functions to enhance productivity.

-

Capturing real-time insights for operations to gain informed decision-making.

-

Eliminating multiple systems and propelling a single-fit application.

-

Gaining the ability to adapt to the dynamic environment to enhance visibility and communication.

-

Providing better services by mitigating risk and enhancing confidence around compliance.

Overall, with the manufacturing business, owning an ERP system extensively aids in supporting the owners and helps the business in increasing with the improved quantity. Analyzing data as efficiently as feasible is critical to quality improvement. Manufacturers usually keep their data in multiple locations at any given time, which adds to the challenges of conducting effective analysis.

What Types of ERP is Best for Manufacturing?

The top manufacturing ERP solutions help adaptable companies adjust to changes and gain a competitive advantage.

There are numerous types of ERP systems and deployment choices available today, which vary widely based on the size, function, and demands of a manufacturing company.

1. On-Premises ERP System:

An on-premises ERP system offers control, support, and ownership of the system once it is implemented. This includes the cost and risk of managing manufacturers' hardware and system infrastructures.

2. Cloud-Based ERP System:

A cloud-based ERP system can offer manufacturers a complete yet flexible system that includes ongoing support, updates, training, and flexible customization from the ERP provider.

3. Hybrid ERP:

A "hybrid ERP" setup can offer a manufacturing organization both on-premises and cloud-based hosting and deployment capabilities. These models allow ERP users to transition between delivery modes or incorporate benefits not available in existing implementations.

Quality Control with ERP Made Easy

Overall, a manufacturing business can enhance product quality and control it at par with informed decision-making. All this comes in handy with manufacturing ERP software.

ERP software improves quality control in manufacturing by providing tools for inventory management, production planning, quality control, resource allocation, and data integration. These solutions assist businesses in streamlining processes, meeting quality standards, and increasing overall manufacturing efficiency.

Enterprises can get more precise control over every aspect of quality management by implementing quality control software plus an ERP system. Some systems go even further by including built-in compliance capabilities, all of which are intended to assist the company in adhering to industry or government norms and laws.

The system also provides access to full control over inspections and end-to-end traceability, which provides faster audits, support, compliance, and the ability to track the supplier's quality.

0 Comments